YX35-273-820 Roof Panel Roll Forming Machine

Easy to operate and running stable.

- item no.:YX35-273-820

- lead time:45

- form speed:18-20m/min

- weight:8 T

1.Main features of YX35-820 roof panel machine roll forming machine

The advantages of roof panel machine are as follows:

1.Low cost, light weight but high strength, short building period, and re-cycle use

2.Save material ,no waste.

3.Easy operation, low maintenance cost

4.Able to deal with stainless material

2.Detailed Images of YX35-820 roof panel forming machine

Machine Parts

1) 1) YX35-820 roof panel machine pre-cutter

With feeding material guide.

22) YX35-820 roof panel machine rollers

Rollers manufactured from high quality 45# steel, CNC lathes, Heat Treatment.

with black treatment or Hard-Chrome Coating for options.

Body framemade from 350# H type steel by welding

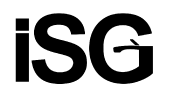

3) 3) YX35-820 roof panel machine post cutter

Made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 20mm steel plate by welding

hydraulic motor:5.5KW, Hydraulic pressure range: 0-16Mpa

4) 4) YX35-820 roof panel machine touch screen

4) 5) YX35-820 roof panel machine control cabinet

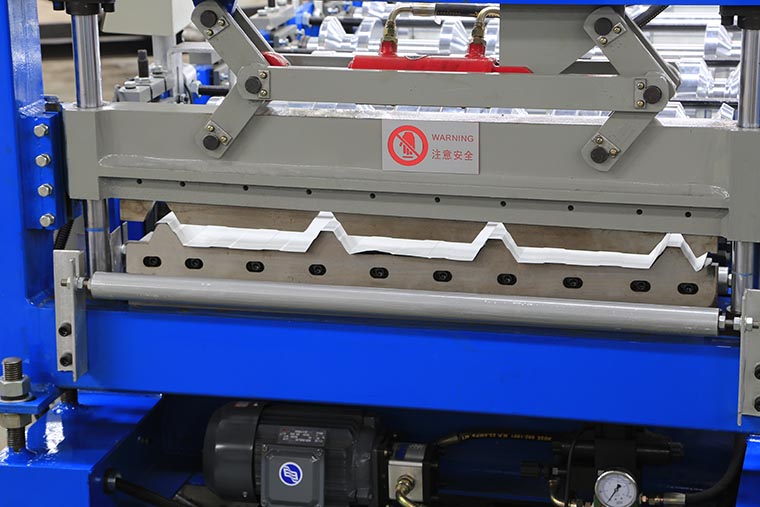

4) 6) YX35-820 roof panel machine product show

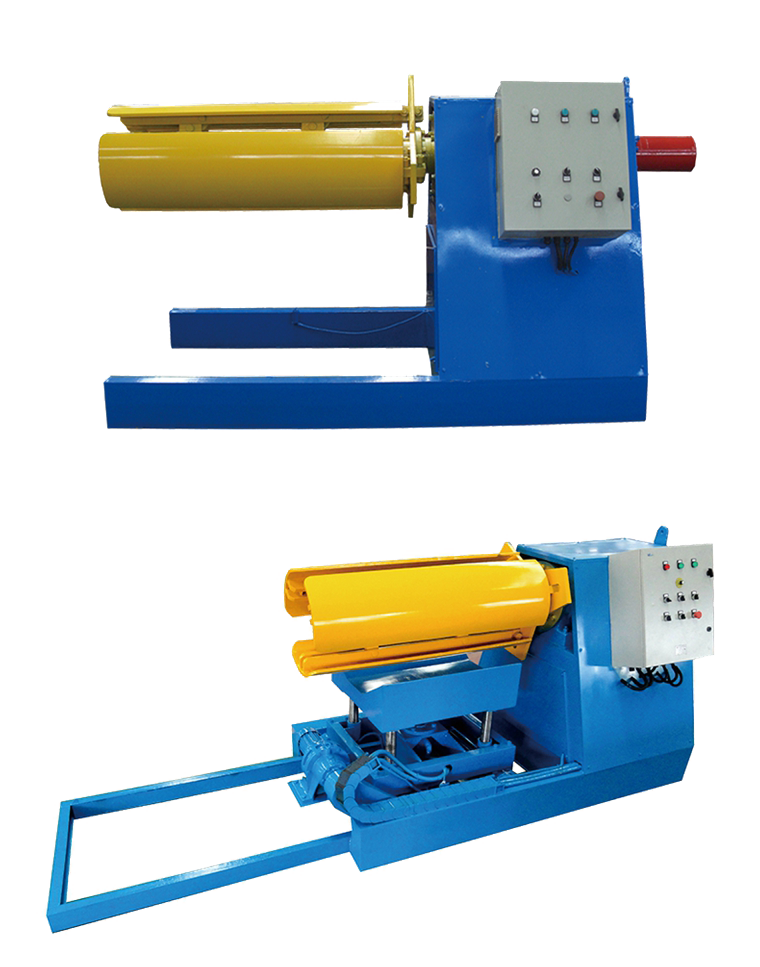

5) 7) YX35-820 roof panel machine decoiler

ManualDecoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 1200mm, coil ID range 508mm±30mm

Capacity: 5-9 Ton With 6 tons hydraulic decoiler for option

8) 8) YX35-820 roof panel machine exit rack

Un-powered,three units

Other detailes of YX35-820 roof panel roll forming machine

Suitable for material with thickness 0.3-0.8mm

Shafts manufactured from 45#,Main shaft diameter=φ75mm,precision machined

Motor driving,Gear chain transmission, 14 steps to form.

Main motor=5.5KW , Frequency speed control. Forming speed approx.12-15m/min

PLC Control System

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-lengthtolerance≤±2 mm

Control Voltage 24V

There are no reviews yet.