Metal Purlin Machine 40-60m/Min High Speed C Stud and Track Roll Forming Machine

| Certification: | CE, ISO9001 |

|---|---|

| Customized: | Customized |

| Condition: | New |

| Control Type: | CNC |

| Automatic Grade: | Automatic |

Material

Effective width:About 80 mm

Material Thickness:0.3-0.6mm

Applicable material: Galvanized Steel(GI)With yield strength G235-390Mpa

Work Follow

Decoiler→Feeding Guide Device→Rolling Forming System→Hydraulic Not Stop Cutting And Punching Device→ Exit Rack

Machine Components

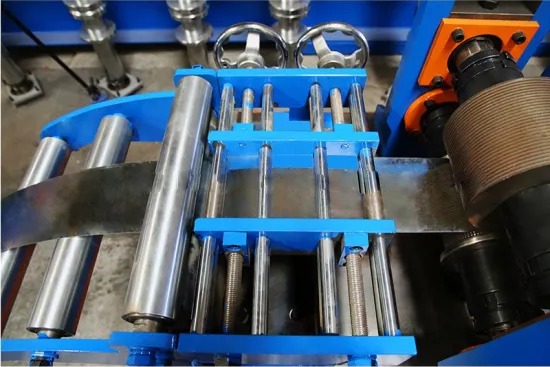

Un-powered, Manually control steel coil inner bore shrinkage and stop

Max Feeding width: 500mm,coil ID range ф460-520mm

Capacity:Max 2 Tons

The feeding guide device at the main entrance of the machine during work,Raw materials on both sides of the plate the enter into the machine by the guiding device,make the raw materials and roll forming system to maintain the correct position.The guiding position can be adjusted by the manual screw mechanism,and the feeding guide width can be adjusted independently

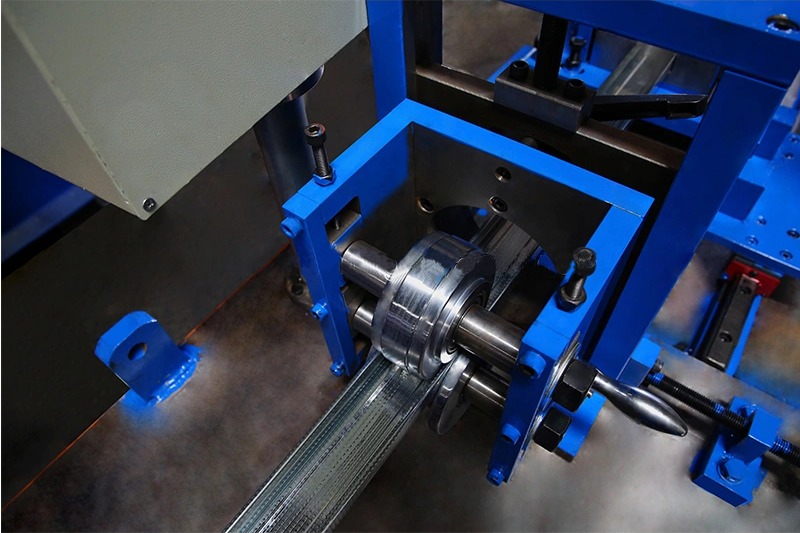

Rolling Forming System

Forming mold: Cr12MoV molding steel, through vacuum quenching heat treatment to HRC60-62 °then grinding the inner

Hole and the end face. The precision machining roller surface with CNC lathe

Shafts material:Cr12 steel,CNC lathes,Heat Treatment,hard Chrome Coated

With thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

Main motor and 12 reducers combination driving,about 14-step to form

Main Motor =5.5KW,Frequency speed control

Hydraulic Cutting Device

Cutter stype:Not stop cutting and punching

The length of tolerance:±1.0mm(3m)

Cutter motor:Hydraulic

Hydraulic Motor:4KW

Servo motor power:1.5 KW

Operation Panel

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, 10 Inch Touch Screen, Encoder, etc

PLC Control System

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,It Can Finish The Production Automatically.

| Combined With | PLC, Inverter, Touch Screen, Encoder, etc |

| PLC | Siemens (German brand)/Schneider(French brand) |

| Inverter | Siemens (German brand)/Schneider(French brand) |

| 7-Inch Color Touch Screen | Siemens (German brand)/Schneider(French brand) |

| Encoder | Omron (Japan brand)Switch Bottom, Indicate Light, Power Supply, Intermediate Relay, AC Contactor |

| Thermal Relay | Siemens(German brand)/Schneider(French brand) |

| Air Switch | LG-LS(Korea brand) Cut-to-Length Tolerance≤±1 mm Control Voltage 24V |

Technical Specifications

| Decoiler | Manual/Hydraulic Decoiler for Options |

| Working Material | Gl |

| Cutter Material | Cr12MOV, Heat Treatment |

| Motor | 5.5kw+4kw+1.5kw |

| Roller Material | Cr12 Steel |

| Control System | PLC Control System |

| Cutting Type | Hydraulic Cutting |

| Speed | 45-60m/Min |

| Station | 12 Stations |

There are no reviews yet.